M5Paper EPD power consumption

-

Hello,

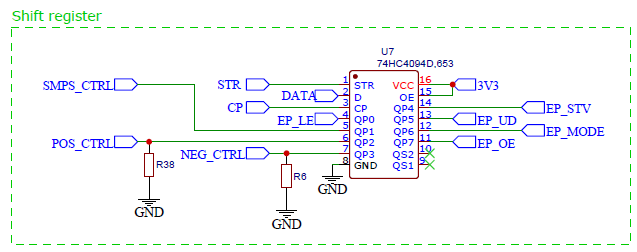

Here is Shift Register schema, the brend is Nexperia.

SYL -

@bricox nice work on mapping out the power management system! I've noticed some peculiarities with the charging PMIC (SLM6635, which does not seem to have any english documentation). Specifically, it does not seem to have a proper measuring system set up while charging. Once you connect it to USB power, the indicated battery voltage is actually the charging voltage of the battery, which can be 20-30% higher than the actual (resting) voltage of the battery. This is quite visible if you let the M5Paper with the FactoryTest firmware run out of battery, then connect it to power and head to the factory test screen - the battery indicator will be between 30-50%, and reported battery voltage will be around 3.7-3.8V (which is impossible on a device that was just completely discharged).

The main problem with this is that the battery cutoff voltage for charging seems to be 4.2V - even though the battery is rated 4.35V officially. You can see this, again, on the Factory firmware, by leaving the unit to charge. Once it hits 4.2V stable, charging is cut to that voltage (and the M5Paper displays ~85% battery left). If you disconnect the charger and reconnect it, charging voltage jumps up to 4.35V, however after some time it stops charging (or switches to trickle charging? Not sure about the inner workings of SLM6635), battery voltage slowly drops to 4.2V, and keeps idling there, requiring another disconnect-reconnect to fully charge it again.

I was wondering, since there seems to be some rudimentary control over power management, would it be possible to reset the charging circuit, or somehow fake the disconnect-connect cycle on it? Even if it's a software workaround, it would be nice to be able to properly charge to maximum capacity - and also it would allow to collect appropriate readings while charging.

What I hope for is that the next M5Paper generation gets a better power management solution, even if it's more expensive. Proper PMIC control - especially in low-power applications where one would use an eink screen with an ESP32 for periodic updates - is incredibly important, and right now, by the looks of it, all we have is analog voltage readouts of VBAT, not even the charging/charging complete signals are hooked up (which are arguably important here as well).

Another thing I thought about regarding power saving - would cutting the power to the EXT ports and the EPD display (via methods

disableEPDPower()anddisableEXTPower()) result in any savings?The cause of this excess consumption is IT8951.

An alternative to this component is the 74HC4094D, 8-stage shift-and-store bus register, used as IO extander.

A competitor with the same display consumes 65 mA, i measured to.Uhm... Pardon my ignorance but according to my research the IT8591 is a full-blown EPD timing controller, not just a bus register. I don't see how the 74HC4094D would be an alternative (most definitely not a drop-in replacement).

-

Hi guys

As @fonix232 pointed out the charging / charging complete signals (NSTDBY / NCHRG) of the battery charger are not hooked up in M5Paper.

So I was wondering, what other external indicator are you guys using to know that the battery has been fully charged? What I mean is how to tell the battery is full w/o running some code checking for the battery voltage every now and then.

Thanks

Felix -

@tatar-andrei said in M5Paper EPD power consumption:

... and without any previous state (unless written to FLASH/SD)...you can also save data into M5Papers EEPROM (FM24C02 - 2K-bit(256x8)-EEPROM) during shutdown.

Thanks

Felix -

@fonix232 said in M5Paper EPD power consumption:

battery cutoff voltage for charging seems to be 4.2V

Hello @fonix232

I also thought the charger is only set for 4.2V cutoff voltage due to the fact that the charger IC in the M5Paper schematics is marked as SLM6600. However the charger IC in my M5Paper actually is a SLM6635 which by default has a charging termination voltage of 4.35V according to its data sheet.

Thanks

Felix -

@felmue then how do you explain that charging voltage is 4.35V until the battery reaches 4.2V, when the charging voltage drops to 4.2V as well?

-

Hello @fonix232

a very good question indeed to which I don't have an explanation (yet).

Another question is how accurate the voltage reported by the ESP32 ADC actually is. There also is a voltage divider and some SCALE factor in the factory test firmware. Interestingly the SCALE factor seems to have changed over time:

#define SCALE 0.5//0.78571429Just curious - did you also verify the battery voltage with a multimeter directly connected to the battery?

Thanks

Felix -

Hi guys

today I did a charging experiment with a fully depleted M5Paper battery. After about 2 hours the charger IC switched from charging to standby (according to the two LEDs I've soldered to the corresponding charger IC outputs).

I used a multimeter (connected directly to the battery) to measure the battery voltage. The voltage from the internal ADC, read via

M5.getBatteryVoltage(), was about 5% higher than the voltage read by the multimeter for voltages below 4.2V. Above that the two values were pretty close. The reason for that is the voltage divider (3k / 11k) which when fed with 4.2V produces about 3.3V to the ADC input which is about the maximum a GPIO can take.The highest voltage I've seen on the multimeter was 4.31V before the charging stopped. After which the voltage dropped back to 4.25V. I think that means the charger IC actually is setup for a 4.35V battery, but for some reason doesn't go all the way up to 4.35V.

Update: a possible reason is explained in the datasheet (Google translated):

==========

_______________Charge termination voltage setting The default full termination voltage V FLOAT set inside the chip is approximately 4.35V, but due to the large charging current, the internal resistance of the battery and the line Loss will cause the actual full-charge termination voltage to be lower than this value, resulting in battery failure The law is full enough. SLM6635 by an external resistor RPV to increase V FLOAT of Voltage, used to compensate various losses, or to satisfy different applications Special requirements for voltage.The compensation voltage can be calculated by the following formula:Delta V = I bat (Standby mode) * RPV

If there is no need to compensate the V FLOAT voltage, it is recommended that RPV be set to 1kΩ.

==========

Thanks

Felix -

@tatar-andrei said in M5Paper EPD power consumption:

I did play around more with power down states and I managed to get a light sleep mode with fast wakeup from touch at around ~9mA.

Hello @tatar-andrei

I tried to get the touch into sleep mode by applying the steps outlined in the GT911 programming guide but I don't see any reduction in power consumption.

The steps are:- switch ESP32 interrupt GPIO from input to output and set it low

- issue command 0x05 to address 0x8040

is there anything else that needs to be done? I'd appreciate your insight on that.

Thank you very much in advance.

Cheers

Felix -

@tatar-andrei said in M5Paper EPD power consumption:

months on a battery charge"

registered a new account for replying this.. not currently a M5Paper owner but will buy one soon!

I happened to be involved in a ESP + 8951 epaper project months ago, the target is months on battery charge (3xAAA battery).

Main env is done using arduino, and scriptable via Lua. UI is rendered on server, send down to the device during idle & stitched with Lua (it's a calendar kind of device).repo is @ https://github.com/luan007/em_playbook

hope some code / impl provides some reference .. -

Hi guys

I just discovered that the voltage divider used to feed the battery voltage into the ADC uses different values from what's listed in the M5Paper schematic.

- M5Paper schematics: 3 kOhm and 11 kOhm -> factor: 0.78571428571

- found in my M5Paper: 10 kOhm and 10 kOhm -> factor: 0.5

With the actual values the modified SCALE factor (0.785.. -> 0.5) found in the library also makes more sense. It compensates the voltage divider.

BTW: when you feed 4.2 V into the original 3 kOhm / 11 kOhm voltage divider you get exactly 3.3 V. So I guess initially M5Paper was designed / planned to use a 4.2 V battery.

Cheers

Felix -

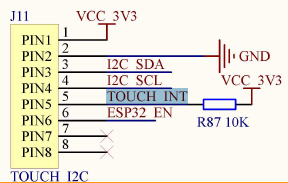

Hi guys

I think I found the reason for why the touch IC (GT911) did not react when I tried to put it into sleep mode. The procedure asks for the ESP32 GPIO used for the touch interrupt to change to an output and then be driven low by the ESP32. Unfortunately GPIO36 is used for the touch interrupt and that is one of the few GPIOs which can only be used as input. So without hardware modification I don't see a way to put the touch IC into sleep mode. Or am I missing something?

Thanks

Felix -

@felmue that definitely sounds like a massive design issue - I wonder, maybe that's why the M5EPD library doesn't have any touchscreen power-off calls?

There was also a post on the M5Stack twitter recently, showing a blurred out image of upcoming devices, with a device eerily similar to the M5Paper taking up a large chunk of the photo: https://twitter.com/M5Stack/status/1357559621389479940/photo/1

I wonder if the design team realised these small issues and made a new board that is more fit for general usage purposes. It happened with the M5Cores (the Basic model had no PSRAM and the first units only had 4MB storage, which later got expanded to 16MB, then the Grey kit came with an MPU, then the Fire kit also included a microphone and PSRAM, among other changes), though the speed is much faster - I think there was almost a year between the Basic and Grey M5Cores, whereas the M5Paper was only recently released.

It does feel like a slap in the face for us who already bought multiple M5Paper units though - we've received a device that has a handful of obvious faulty design choices, and now we have to buy the new, updated model to get functionality that should've been working in the first iteration. Don't get me wrong, I'm happy for the updated design, I just hope there will be some discount for those who've already got units on their hands.

-

You mention that you got the touch wakeup working. Could you share how you managed to do this?

I have searched and tried everything. I have had no luck with the touch wakeup. Currently my Homekit panel runs for about 5 hours without any sleep setup. This is just too low. I only need to use it couple of times a day and most of the time it should be on sleep.

-

Hi guys

I went ahead and modified my M5Paper so it can put the touch IC (GT911) into sleep mode. By doing so the current (measured at the battery) drops about 7.6 mA.

With WiFi off, EDP power off, ESP32 in deep sleep and touch in sleep mode the overall current is about 1.6 mA.

Note: since putting touch into sleep mode requires touch INT to be driven low by ESP32, touching the screen can no longer be used to wake up M5Paper.

Cheers

Felix -

@felmue

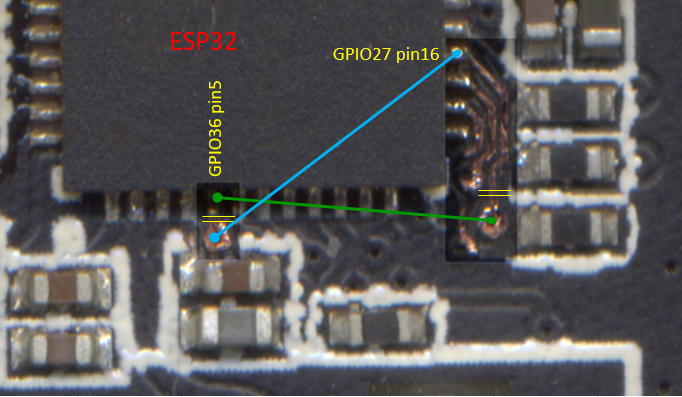

Indeed GPIO36 is only input.

So I looked for another GPIO used only as input to reverse the 2 GPIO on the pcb.

I found the GPIO27 which tells ESP32 that the IT8951 is ready for a SPI dialogueIT_SPI_HRDY (schema)

#define M5EPD_BUSY_PIN 27 (M5EPD.h)

EPD.begin(M5EPD_SCK_PIN, M5EPD_MOSI_PIN, M5EPD_MISO_PIN, M5EPD_CS_PIN, M5EPD_BUSY_PIN); (M5EPD.cpp)

m5epd_err_t M5EPD_Driver::begin(int8_t sck, int8_t mosi, int8_t miso, int8_t cs, int8_t busy, int8_t rst)

_pin_busy = busy;

pinMode(_pin_busy, INPUT);

On my pcb, the resistance R87 is absent (unwelded)

All you have to do is reverse the 5 and 16 tabs on the ESP32.

I scraped the varnish and then scanned the pcb.

You have to cut the 2 tracks between the 2 pins of the esp32 and the 2 vias.

then solder 2 thin wires. -

-

Hello @bricox

very elegant solution. Thank you for sharing.

I opted to leave GPIO36 as is and connected GPIO19 (from port C) in parallel which I can then set to output if I want to use touch sleep mode. (Yes, I loose port C, but it made the soldering a bit easier. Only one additional wire from a pin on port C to the unpopulated R87 pad.)

Cheers

Felix -

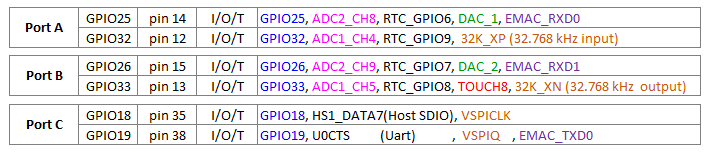

@felmue

I did a summary of the 3 ports A, B and C

You made a good choice using GPIO19.

Indeed, welding work is simplified.

Do you share your source code? -

Hello @bricox

@bricox said in M5Paper EPD power consumption:

Do you share your source code?

Sure, you can find my touch sleep mode test sketch here.

It's a extended version of the TOUCH example which uses the left/up button to set touch into normal mode and right/down button to set into sleep mode.

Cheers

Felix