Possible issue with Tab5 and UiFlow v2.3.1 - (i2c driver install error)

-

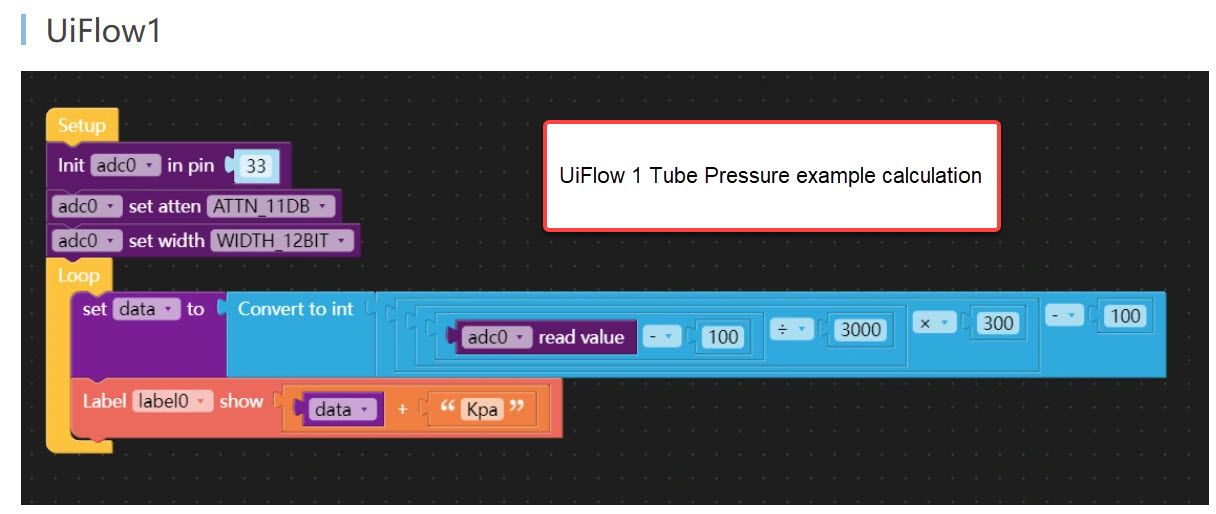

try with analog value, delete get voltage block

on your original "tube pressure" example use raw analog value for start too

-

Hi guys

I tested M5Tab5 (running UIFlow 2.3.1) with all the units I have available and most of them worked ok.

Note: I also got the

i2c driver install error, but it didn't cause I2C to actually fail.GPIO units

- SSR - ok

I2C units (bus speed 100k)

- Env III - ok

- Env IV - ok

- ExtIO2 - ok

- Color LCD - ok

- OLED - ok

- PaHUB - Env IV - ok

I2C units (bus speed 400k)

- PbHUB - ok

- 4Relay - ok

Unit Gesture and AMeter did not work for me with either bus speed 100k or 400k. M5Tab5 seemed to hang in setup and a hard reset was required.

Thanks

Felix -

This post is deleted! -

@felmue - Thanks felmue for tube air sensor with your Tab 5 with UIFlow 2.3.1! So your UIFlow test program with the Tube air sensor connected to Port A successfully uploaded to the Tab5 and captured air pressure readings? If so, can you post a screen shot of your simple program you used to test the sensor with?

I wonder what is causing i2c driver install error to be generated.

I will give it another try with the suggestions robski made but if you could post your testing code that ran successfully that would great!

-

Hello @Kenzo

I think you might have misread my post. I do not have a Tube Pressure unit so I cannot test this case, sorry.

Thanks

Felix -

@felmue Yep, I read that wrong... my fault...

-

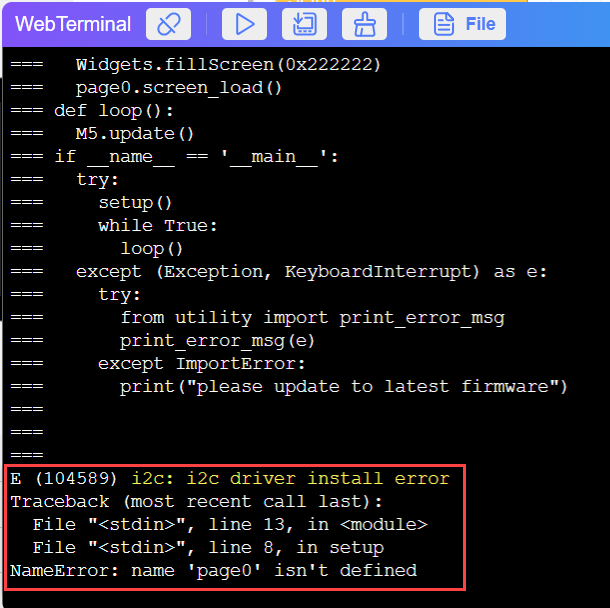

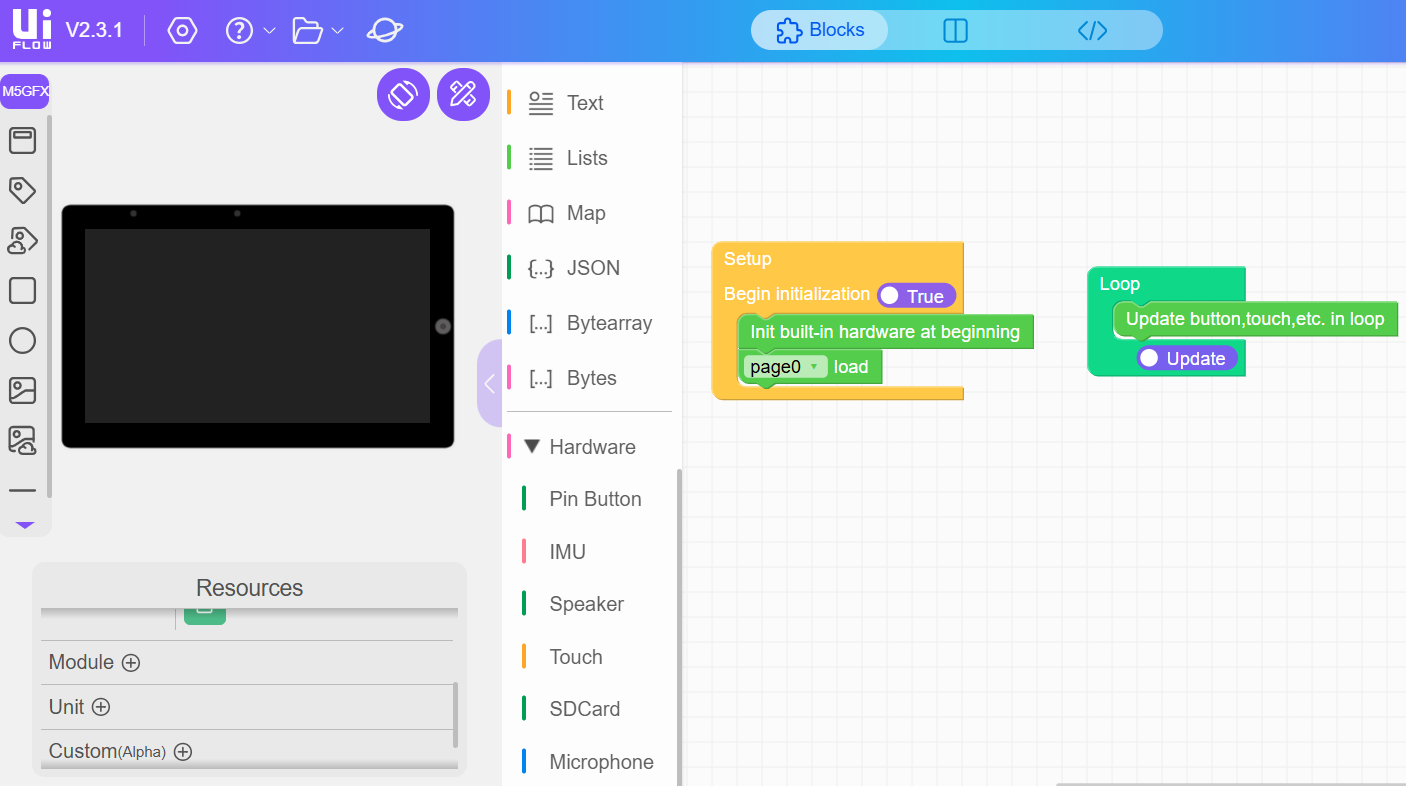

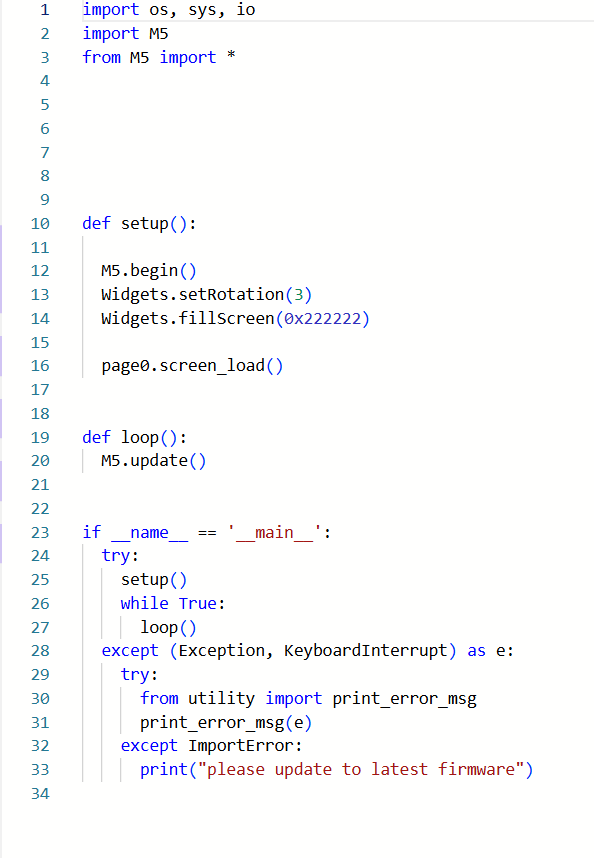

Well I started doing the process of elimination and decided to compile a default blank Tab5 project in UiFlow v2.3.1 with no unit sensors and the i2c driver install error still occurred... See screen shots... So something else is trying to load the i2c drivers in UiFlow v2.3.1 for the Tab5 device and is having a problem installing it...

Question: Could this be a possible bug somewhere when it comes to Tab5 and the UiFlow IDE???

-

i'm getting the same i2c driver error on an Atom Lite, the error began following an erase but persists regardless of the UIflow2 version I attempt to refresh with.

-

Hello guys

I think that is what I wanted to tell you guys with my previous post. The

i2c driver install error, which I also get, does not prevent most of my units to work properly.Out of all my units only two did not work and two I2C units would only work after switching the i2c speed to 400 k.

In other words I do not think the

i2c driver install errormatters in regard with the Tube Pressure unit, which is not an I2C unit.@Kenzo : do you have any other units you could try with your M5Tab5? Or any other core(s) you could try the Tube Pressure unit with?

Thanks

Felix -

in my case i need to query an AIN unit, which is i2c...so this error is a total blocker.

-

@Kenzo as Ive said before try below: remove "get voltage" block and try your Tube Pressure unit with analog value only

-

@adamm5 Ive rebuilt this project from scratch and can confirm that ignoring the i2c load error is possible even when using the AIN i2c unit and PAhub unit. This seems to be a change to my earlier experience but perhaps something else was happening with the code.

-

Thanks everyone for your suggestions!

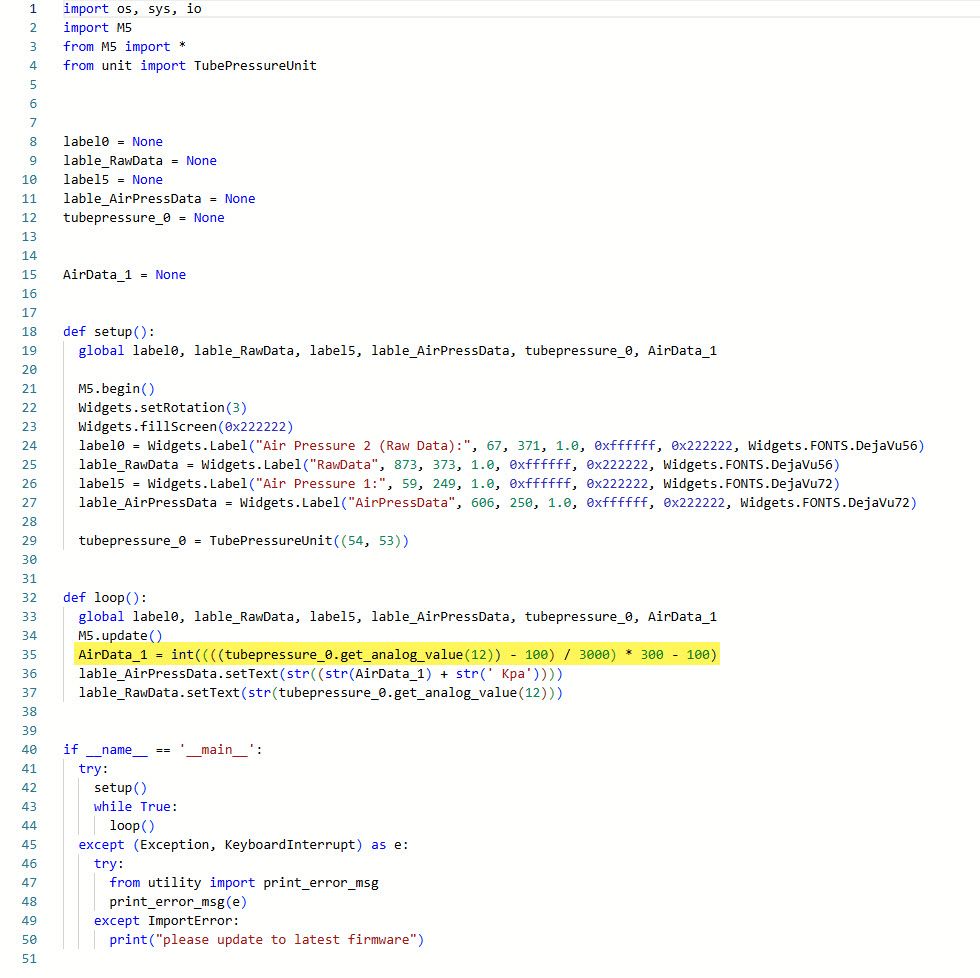

@robski - I went back to my Tube example and the only one that worked was the ADC parameter to pull data. (I used 12bit)

So I looked at the UiFlow1 example for the Tube Pressure and tried to duplicate it. The program now runs BUT I am not sure if I am using the correct math conversion to convert the raw data from the ADC parameter into Kpa. I have searched a couple of sources BUT can't seem to find documentation that fully explains how to correctly calculate Kpa with the ADC parameter to Kpa...

Does anyone know were to get really good documentation on the tube pressure sensor that explains how to properly calculate Kpa using the sensor with ADC option?

-

So if I assume the ADC 12 bit option will give me 4,096 different points and the ADC 16 bit option will give me 65,536 different points maybe I can come up with a formula ( using the voltage - Pressure graph) of how to calculate Kpa when using ADC option for the Tube pressure... Everyone I am just thinking out loud so don't bash me too badly... LOL!

-

what are RAW values you are getting from your sensor? pure analog read value?

try below

float raw = analogRead(sensorPin); // Read analog value

float Vout = raw / 4095.0 * 3.6; // Convert to voltage (assuming 3.6V reference)

float P = (Vout - 0.1) / 3.0 * 300.0 - 100.0; // Calculate pressure in kPa -

@robski Thanks for replying! With nothing connected to the Tube pressure sensor, I am getting a RAW value of 3,287 (12 bit option selected in the ADC parameter).

In regards to a 3.6V reference, where is that in the documentation?

I think we are getting close to solving this problem!

-

@robski - I stumbled across this youtube video about an Arduino Pressure Sensor and was thinking about testing a version of his method for coming up with a calculation...

-

with your raw value as 3287

sensor range -100 to 200

analog range 0 to 4095your calculated pressure should be around 140

-

@robski - hmmm.... Well that raw value was with nothing connected to the Tube Pressor sensor. Because nothing is connected to the tube pressure sensor I would assume it would be closer to 0 Kpa... 140Kpa is a big difference from 0 Kpa... I wonder what we are missing?

-

@robski I keep coming up with 140Kpa also...

We must be missing something...